Ever wondered what makes your lawnmower roar or your jetski zip across the water? The answer lies in a powerful little engine called a two-stroke engine. Unlike its four-stroke counterpart found in most cars, two-stroke engines deliver a simpler design and a punch of power, making them ideal for various applications.

This comprehensive guide dives deep into the world of engines, explaining their inner workings, highlighting their advantages and disadvantages, and showcasing the machines where they truly shine. So, buckle up and get ready to learn about these rev-happy engines!

Demystifying the Two-Stroke Cycle: Two Strokes to Power

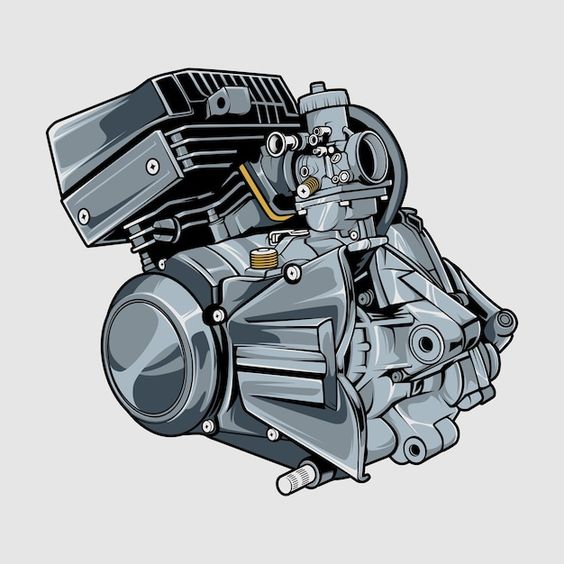

At the heart of a two-stroke engine lies a unique cycle that accomplishes the tasks of intake, compression, combustion, and exhaust in just two piston strokes – a stark contrast to the four strokes required in a traditional engine. Here’s a breakdown of this streamlined process:

-

Downward Stroke (Compression and Intake): As the piston moves down the cylinder, it creates a vacuum beneath it. This vacuum sucks in a fresh air-fuel mixture through transfer ports on the crankcase (the lower section of the engine that houses the crankshaft). Simultaneously, the rising piston in the cylinder compresses the existing air-fuel mixture above it.

-

Upward Stroke (Combustion and Exhaust): When the piston reaches its bottommost position, a spark plug ignites the compressed air-fuel mixture, creating a powerful explosion that drives the piston back up. This upward stroke forces the burnt gases out of the exhaust port located near the top of the cylinder. As the piston continues to rise, it uncovers the transfer ports, allowing the fresh air-fuel mixture from the crankcase to flow into the cylinder, completing the cycle and prepping for the next combustion event.

This two-stroke cycle is what gives engines their characteristic simplicity. By eliminating the need for valves (which control intake and exhaust in four-stroke engines), two-stroke engines boast fewer moving parts, resulting in a lighter weight and easier maintenance.

Power Up Your Ride: Advantages of Two-Stroke Engines

The unique design of two-stroke engines offers several advantages that make them a popular choice in specific applications:

-

High Power-to-Weight Ratio: Due to their simpler design and the ability to generate power with every revolution of the crankshaft, engines deliver impressive power for their size. This makes them ideal for powering lightweight machines like chainsaws, weed whackers, and motorcycles.

-

Simple Design: With fewer moving parts, two-stroke engines are generally easier and cheaper to manufacture and maintain compared to their four-stroke counterparts. This translates to lower costs for consumers.

-

Light Weight: The lack of complex valve mechanisms makes two-stroke engines significantly lighter than four-stroke engines. This is crucial for applications where weight is a major concern, such as in airplanes and ultralight vehicles.

-

Simple Operation: Two-stroke engines often don’t require a complex lubrication system. Instead, oil is pre-mixed with the fuel, simplifying the operation and maintenance process.

Not All Sunshine and Rainbows: Disadvantages of Engines

While engines offer several advantages, they also come with some drawbacks that limit their use in certain applications:

-

Emissions: Due to the mixing of oil with fuel and the less efficient burning process, engines tend to produce higher emissions compared to four-stroke engines. This has led to stricter regulations on their use in some regions.

-

Fuel Efficiency: The process of scavenging (using fresh air-fuel mixture to push out exhaust) can sometimes lead to a loss of unburnt fuel, resulting in lower fuel efficiency compared to four-stroke engines.

-

Oil Consumption: As oil is pre-mixed with fuel in engines, they tend to consume more oil than four-stroke engines that have a dedicated lubrication system.

-

Noise Levels: The simpler design and higher combustion rates of engines often result in louder operation compared to four-stroke engines.

Built for Speed: Where Two-Stroke Engines Reign Supreme

Despite their limitations, engines remain the preferred choice for powering various machines due to their specific strengths:

-

Lawnmowers and Weed Whackers: The lightweight design and high power output of engines make them ideal for powering lawnmowers and weed whackers, allowing for effortless yard maintenance.

-

Chainsaws: Engines provide the perfect combination of power and portability for chainsaws, making them essential tools for professional loggers and casual homeowners alike.

-

Jet Skis and Other Watercraft: The simplicity and high power-to-weight ratio of engines make them perfect for powering jet skis and other personal watercraft, delivering an exhilarating ride on the water.

Fueling the Flame: How Two-Stroke Engines Get Going

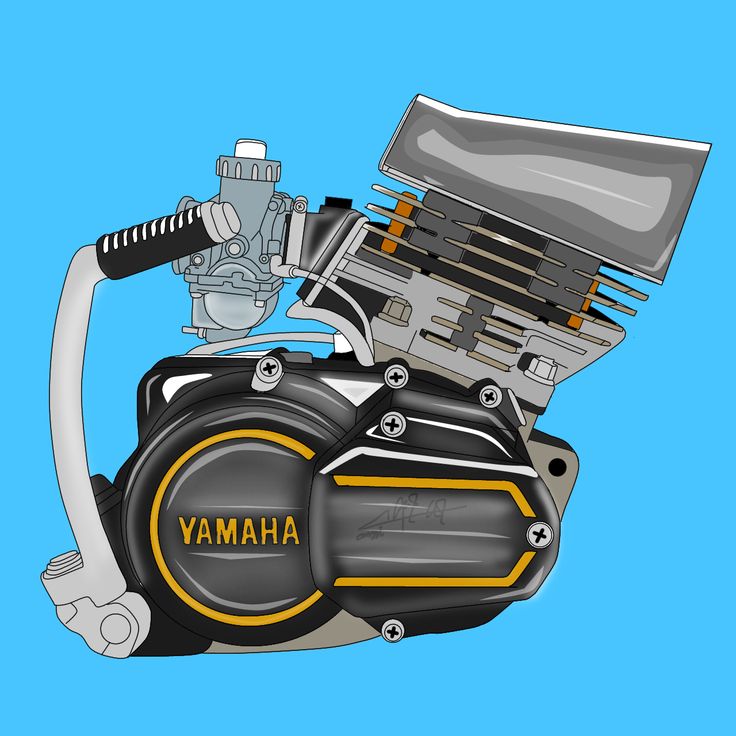

Unlike four-stroke engines that have a dedicated oil system, engines rely on a pre-mixed fuel and oil combination. This mixture ensures proper lubrication for the piston and other moving parts within the engine. The specific oil-to-fuel ratio is crucial and varies depending on the engine manufacturer’s recommendations. Using the incorrect ratio can lead to engine damage or decreased performance.

The pre-mixed fuel is typically drawn into the engine through the carburetor by the vacuum created by the crankcase during the upward stroke of the piston. As the piston descends, the fresh air-fuel mixture is compressed in the cylinder.

At the precise moment, the spark plug ignites the compressed mixture, creating a powerful explosion that drives the piston back up. This upward stroke forces the burnt gases out of the exhaust port and uncovers the transfer ports, allowing the fresh air-fuel mixture from the crankcase to flow into the cylinder, prepping for the next combustion event.

This continuous cycle of intake, compression, combustion, and exhaust keeps the two-stroke engine running and powering the machine.

The Future of Two-Stroke Engines: Innovation and Environmental Concerns

Two-stroke engines have played a vital role in powering various machines for decades. However, their higher emissions have led to stricter regulations and a push for cleaner technologies.

Here’s a glimpse into the future of engines:

-

Emission Reduction Technologies: Manufacturers are constantly developing new technologies like stratified scavenging and direct fuel injection to improve fuel efficiency and reduce emissions from two-stroke engines.

-

Electric Alternatives: The rise of electric motors presents a significant challenge to engines, particularly in smaller applications. Electric motors offer quieter operation, zero emissions, and require less maintenance.

-

Continued Use in Niche Applications: Despite the challenges, two-stroke engines are likely to remain in use for niche applications where their power-to-weight ratio and simplicity offer distinct advantages.

The future of two-stroke engines hinges on their ability to adapt to stricter environmental regulations. Whether through cleaner burning technologies or strategic use in specific applications, engines will likely continue to play a role in the world of internal combustion engines for years to come.