The engine is the beating heart of a car, and at the center of this vital component lies the engine block. This unassuming chunk of metal is the foundation upon which the entire engine is built. But what exactly is an engine block, and why is it so crucial?

Unveiling the Engine Block: A Deep Dive

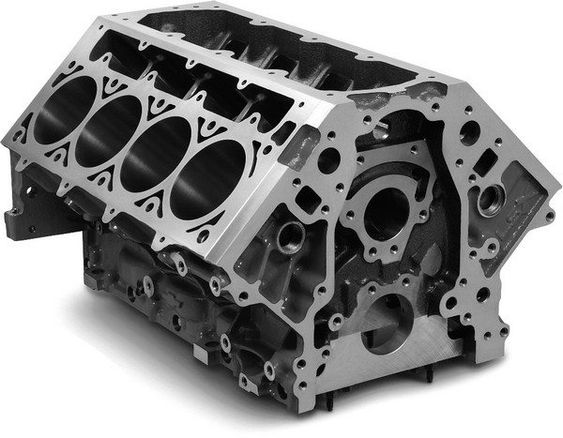

An engine block, also sometimes referred to as a cylinder block, is the core structure of an internal combustion engine. Imagine it as the housing that cradles all the essential components responsible for generating power. The block is typically made from robust materials like cast iron or aluminum alloy, designed to withstand the immense heat and pressure produced during combustion.

Delving into the Block’s Responsibilities: What Does it Do?

The engine block fulfills a multitude of critical tasks within the engine. Here’s a breakdown of its key functionalities:

-

Housing the Cylinders: The block contains cylindrical bores known as cylinders. These are the chambers where the pistons move up and down, driving the engine’s operation. The number of cylinders in an engine block varies depending on the engine’s design and power output. Four-cylinder engines are common, but engines can have anywhere from three to twelve cylinders, or even more in high-performance applications.

-

Supporting the Crankshaft: The crankshaft is a crucial rotating shaft located within the block. Its function is to convert the reciprocating motion of the pistons (up and down) into rotational motion, which is then transmitted to the wheels. The block provides support and ensures proper alignment for the crankshaft’s smooth operation.

-

Providing Channels for Lubrication and Cooling: The intense heat generated during combustion necessitates efficient cooling. The block typically features a network of passages that allow coolant to circulate around the cylinders, absorbing and carrying away heat. The block also incorporates oil galleries that deliver oil to lubricate moving parts within the engine, minimizing friction and wear.

-

Mounting Platform for Other Components: The engine block serves as the foundation for attaching other essential engine components. These include the cylinder head, which seals the top of the cylinders and houses the valves, the intake manifold that delivers air to the cylinders, and the exhaust manifold that carries away exhaust gases.

Evolution of the Engine Block: A Historical Perspective

The engine block has undergone significant advancements throughout automotive history. Early engines utilized individual cylinders bolted together, but this approach proved cumbersome for mass production. The invention of the single-piece cast iron block revolutionized engine manufacturing, allowing for a more robust and cost-effective design.

Modern engine blocks are often constructed from aluminum alloys, offering several advantages. Aluminum is lighter than cast iron, contributing to improved fuel efficiency. Additionally, aluminum conducts heat more effectively, aiding in engine cooling. However, some high-performance applications still favor cast iron blocks due to their superior strength and durability under extreme loads.

Beyond the Basics: Exploring Different Block Designs

Engine blocks come in various configurations based on the engine’s layout and cylinder arrangement. Here are some common types:

-

Inline Engines: In inline engines, the cylinders are arranged in a single row, one behind the other. This is a simple and compact design often found in four-cylinder engines.

-

V-Engines: V-engines feature two cylinder banks positioned in a V-shape. This configuration allows for a more powerful engine within a relatively compact space. V6 and V8 engines are popular examples.

-

Flat Engines: Flat engines, also known as boxer engines, have horizontally opposed cylinders. This design offers a lower center of gravity, which can enhance handling characteristics. Subaru is a well-known manufacturer that utilizes flat engines in many of its vehicles.

Maintaining the Engine Block: Ensuring Optimal Performance

The engine block is a vital component, and its longevity depends on proper engine maintenance. Regular oil changes are essential to ensure clean and lubricated internal components. Additionally, using the recommended coolant and maintaining a proper coolant level is crucial for effective engine cooling. Following the manufacturer’s maintenance schedule and addressing any potential leaks or issues promptly will contribute significantly to the lifespan of your engine.

Upgrading the Engine Block: Boosting Power (Optional Section)

For performance enthusiasts, modifying the engine can be an option to increase power output. However, such modifications are typically complex and expensive, and it’s crucial to consult with experienced mechanics before undertaking any significant alterations.

The Engine Block: The Unsung Hero Under the Hood

In conclusion, the engine is the unsung hero within a car’s engine. This robust and meticulously crafted component serves as the foundation for the entire power generation process. Understanding the engine block’s role and importance can empower you to appreciate the intricate workings of your car’s engine and take steps to ensure its optimal performance for miles to come.

Don’t Get Blocked Out! Troubleshooting Common Engine Block Problems

While the engine block is a durable component, it’s not invincible. Here’s a look at some common engine block problems and their warning signs:

-

Overheating: Excessive engine heat is a major threat to the block’s integrity. Symptoms include a temperature gauge reading in the red zone, a loss of coolant, or the smell of burning coolant. Causes can be a faulty thermostat, clogged radiator, or a failing water pump. If you experience overheating, pull over immediately and shut off the engine to prevent severe damage.

-

Cracked Block: Though uncommon, cracks in the engine block can occur due to severe overheating, improper engine modifications, or metal fatigue. Signs of a cracked block include external coolant leaks, a milky white substance in the engine oil (indicating coolant mixing with oil), or rough engine idle. A cracked block is a serious issue requiring professional repair or engine replacement.

-

Blown Head Gasket: The head gasket seals the cylinder head to the engine block. A blown head gasket can cause coolant or oil leaks, rough idling, and loss of engine power. Causes include overheating or using an incorrect head gasket. Repairing a blown head gasket involves replacing the gasket and potentially resurfacing the cylinder head or engine.

-

Knock or Pinging: A persistent knocking or pinging sound from the engine could indicate detonation, which is abnormal combustion caused by low-octane fuel or engine problems. Detonation can put stress on the engine and other components. Using the recommended octane fuel and addressing any underlying engine issues can help prevent detonation.

When to Seek Professional Help: Recognizing When You Need an Expert

Diagnosing and repairing engine block problems can be complex. If you suspect an issue with your engine block, it’s crucial to seek help from a qualified mechanic. They possess the expertise and tools to accurately diagnose the problem and recommend the appropriate course of action, which may involve repairs or, in severe cases, engine replacement.

Investing in Your Engine’s Future: The Importance of Preventive Maintenance

The best defense against engine problems is a proactive approach to maintenance. Here are some key practices:

-

Regular Oil Changes: Clean engine oil minimizes friction and wear on internal components, including the engine block. Follow the manufacturer’s recommended oil change intervals and use high-quality oil.

-

Coolant Maintenance: Coolant plays a vital role in regulating engine temperature. Regularly checking and replacing coolant ensures optimal cooling performance and protects the engine block from overheating.

-

Visual Inspections: During routine maintenance, mechanics will visually inspect the engine block for any leaks, cracks, or signs of damage. Addressing minor issues promptly can prevent them from escalating into bigger problems.

-

Following the Manufacturer’s Recommendations: Your car’s owner’s manual contains valuable information on recommended maintenance schedules and service procedures. Adhering to these guidelines will contribute to the overall health and longevity of your engine.

By prioritizing preventive maintenance, you can significantly reduce the risk of encountering costly engine block issues down the road.

Ready to Dive Deeper? Explore the World of Engine Blocks!

The world of engine is vast and fascinating. If you’re curious to learn more, here are some resources to explore:

-

Online Resources: Numerous websites and automotive forums offer in-depth information on engine block design, function, and troubleshooting.

-

Repair Manuals: Haynes and Chilton repair manuals provide detailed instructions and diagrams for specific car models, including information on engine maintenance and repair procedures.

-

Community Engagement: Participating in online car enthusiast communities allows you to connect with other car owners, mechanics, and enthusiasts who can share valuable knowledge and experiences related to engine blocks.

By delving deeper into the world of engine blocks, you can gain a newfound appreciation for this critical automotive component and its role in powering your car.