Chain guards serve a fundamental purpose in various applications, from bicycles to machinery and industrial equipment. Their primary function is to cover and protect chain mechanisms from dirt, debris, and potential hazards that could affect performance and safety. Chain guards come in various shapes, sizes, materials, and designs, depending on their intended use and the environment in which they operate. Proper installation and maintenance of chain guard ensure optimal performance while preventing damage to chains, sprockets, or other equipment components. This article will explore the importance of chain guards in different contexts, types of chain guard available, installation practices, maintenance tips, and their impact on machinery and safety. By the end, you will have a comprehensive understanding of chain guards and their vital role across various applications.

The Functionality of Chain Guard

Chain guard provide essential protection for chain systems, and understanding how they function can help you recognize their importance. At their core, chain guard serve to keep chains clean and free from contaminants while preventing accidents and injuries.

1. Protection Against Debris

When operating machinery or riding a bicycle, debris can easily hinder the functionality of a chain. Rocks, dirt, and other particles can lead to wear and tear, impacting performance. Chain guard act as a barrier, safeguarding chains from such harmful elements and ultimately extending their lifespan.

2. Enhanced Safety Measures

In both bicycles and industrial applications, exposed chains can pose significant safety risks to users. Loose clothing or body parts can become entangled in the chain or sprockets, leading to serious injuries. Installing chain guards helps mitigate these risks by covering the moving parts and keeping them safely enclosed.

3. Improved Efficiency

A well-maintained chain operating in a clean environment performs better and operates more efficiently. By preventing dirt accumulation, chain guard help maintain optimal functioning, ensuring that the system runs smoothly without additional strain.

Types of Chain Guard

Chain guard are available in several configurations, each designed to meet specific needs and applications. Below, we outline the most common types of chain guard and their unique benefits.

1. Bicycle Chain Guard

Bicycle chain guard are designed to protect the chain on bikes, particularly for commuter or utility styles. They help keep dirt, grime, and debris away from the chain while also preventing clothing from getting caught.

Features of Bicycle Chain Guard

- Full Enclosure: Some bicycle chain guard fully encase the chain, providing maximum protection but may require more delicate installation.

- Partial Guards: These guards cover only the upper portion of the chain, allowing for easier access for cleaning and maintenance while providing some protection.

2. Motorcycle Chain Guards

Motorcycles utilize chain guards to protect the rear drive chain, ensuring optimal performance and rider safety. They are typically made of durable materials that can withstand harsh environments and impacts.

Features of Motorcycle Chain Guards

- Design Variations: Motorcycle chain guards come in various designs, including those that complement the bike’s aesthetics while offering practical protection.

- Enhanced Durability: Often made from strong plastics or metals, these guards withstand exposure to road debris, oil, and weather conditions.

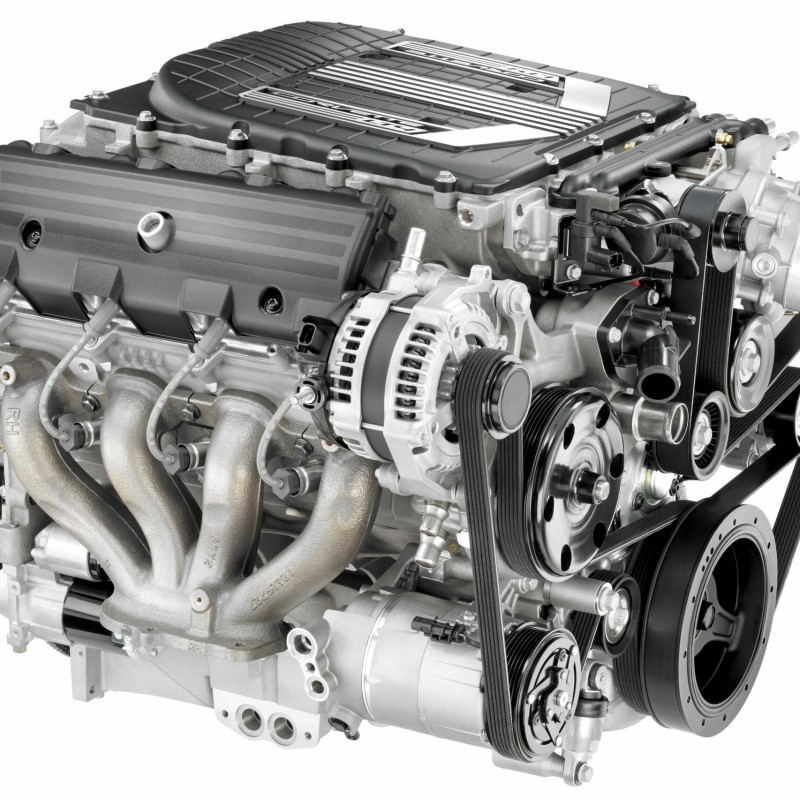

3. Industrial Chain Guards

In industrial applications, chain guards protect heavy-duty machinery, conveyor systems, and other equipment that operate with chains. Their design usually prioritizes durability and safety in harsh environments.

Features of Industrial Chain Guards

- Heavy-Duty Materials: These guards typically use robust materials like stainless steel or reinforced plastic to withstand wear and tear.

- Customizable Designs: Industrial chain guards can be specifically designed to fit various machinery configurations, ensuring compatibility and performance.

4. Custom Chain Guards

For specialized applications, custom chain guards can be designed according to specific requirements. These guards can provide tailored solutions for niche markets or unique machinery.

Customization Options

- Material Selection: Choose from various materials based on environmental conditions and durability needs.

- Dimensions and Shapes: Manufacturers can create specific dimensions and shapes to match the machinery or application.

Installation of Chain Guards

Proper installation of chain guards is essential for maximizing their protective benefits. The following steps will guide you through a successful installation:

1. Gather Tools and Supplies

Before beginning the installation, ensure you have all necessary tools and supplies. Common items include:

- Chain guard

- Mounting hardware (brackets, screws, etc.)

- Wrenches or screwdrivers

- Measuring tape

- Safety goggles

2. Measure the Area

Before installing the chain guard, accurately measure the area where the guard will be placed. Take into account the specific space requirements of your application to ensure a fitting installation.

3. Prepare the Chain Area

Before attaching the chain guard, clean the surrounding area of dirt, grease, or debris. This ensures a secure fit and prevents contamination from entering the mechanism once the guard is mounted.

4. Installation Process

- Position the Guard: Align the chain guard with the designated area and hold it in place.

- Secure the Guard: Use the mounting hardware to attach the guard securely to the frame or designated area.

- Double-Check Stability: After installing, confirm that the guard remains stable and doesn’t interfere with the chain’s movement.

5. Final Inspection

After installation, perform a thorough inspection of the chain guard. Test the functionality of the chain, ensuring that it operates smoothly without obstruction.

Maintenance of Chain Guards

To ensure that chain guards function effectively, regular maintenance is necessary. Here are some important practices to consider:

1. Regular Cleaning

Over time, chain guards may accumulate dirt, grease, and debris. Periodically cleaning the guard keeps it functional and prevents contamination of the chain. Use mild soap and water with a soft cloth or sponge for cleaning.

2. Inspect for Damage

During your maintenance routine, inspect the chain guard for any signs of wear, cracks, or damage. Replace any compromised guards to ensure continued protection.

3. Verify Attachment Security

Ensure that the chain guard remains securely attached to the frame or designated area. Periodically check the mounting hardware for tightness, adjusting as necessary to prevent any movement.

4. Lubricate Chains

Though not directly related to the chain guard’s maintenance, keeping the chain well-lubricated can improve overall performance. Regularly applying lubricant helps reduce friction and wear, further prolonging the life of the chain and guard.

5. Follow Manufacturer Guidelines

Always consult the manufacturer’s recommendations for specific maintenance requirements for your type of chain guard. Adhering to guidelines ensures optimal performance and safety.

Common Issues and Solutions

Understanding common issues that may arise with chain guards can help you troubleshoot effectively. Here are some potential problems and solutions:

1. Misalignment of the Chain Guard

If a chain guard becomes misaligned, it may lead to noises or hinder the chain’s functions. If this occurs, follow these steps:

- Check the Installation: Verify that the guard has been installed correctly and securely.

- Realign and Retighten: If necessary, realign the guard and retighten the mounting hardware to ensure a secure fit.

2. Damage from Impacts

Chain guards can sustain damage over time, especially in high-traffic areas or rough environments. If you notice cracks or breaks:

- Inspect and Assess: Assess the severity of the damage.

- Replace if Necessary: If damaged, replace the guard promptly. Continuing to use a damaged guard can lead to further issues with the chain system.

3. Accumulation of Debris

A build-up of dirt or debris can hinder the effectiveness of a chain guard. To address this issue:

- Regular Cleaning: Establish a regular cleaning routine to ensure that the guard remains clear of contaminants and debris.

- Inspect Your Environment: Additionally, if your working environment is prone to exposure, consider installing additional shields or barriers to minimize debris accumulation.

The Future of Chain Guards

The evolution of chain guards reflects advancements in materials and design in the ongoing quest for improved safety and performance. Innovations in technology and materials will influence the future of chain guards:

1. Smart Chain Guards

With rising trends in smart technology, future chain guards may incorporate sensors to monitor chain performance and wear levels. Such enhancements will allow for real-time feedback to users, facilitating informed maintenance decisions.

2. Advanced Materials

As materials continue to evolve, lightweight and durable options will likely gain prevalence. Innovations such as polymer composites and reinforced plastics could lead to stronger, more efficient chain guards that withstand harsh environmental conditions.

3. Enhanced Customization

Greater customization options will likely emerge, allowing manufacturers and users to tailor chain guards to their specific needs. This flexibility will enhance performance and safety in various applications.

Conclusion

In summary, understanding chain guards and their importance in various applications is crucial for ensuring the performance and safety of equipment. Whether for bicycles, motorcycles, or industrial machinery, these protective components play a significant role in maintaining functionality while mitigating risks.

Choosing the right type of chain guard, installing it with care, and maintaining it properly can lead to extended longevity and optimized performance. As technology progresses, the opportunities for innovative and smarter chain guards will only grow, enhancing their capabilities further. By remaining proactive, you can ensure that your equipment remains safe, effective, and ready for any challenge ahead.