Engine mounts are a crucial component in any vehicle, playing a key role in ensuring a smooth and stable ride. Yet, many drivers are unaware of how often engine mounts break and what signs to look for. Understanding the frequency and causes of engine mount failure can help you maintain your vehicle’s performance and safety. In this comprehensive guide, we will explore how common engine mount issues are, their causes, and what you can do to prevent and address them.

Understanding Engine Mounts

What Are Engine Mounts?

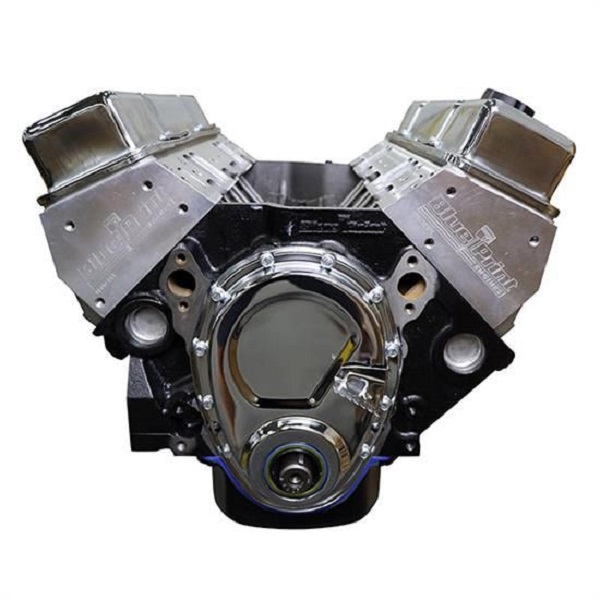

Engine mounts are brackets or supports that secure the engine to the vehicle’s frame. They are designed to absorb vibrations and reduce noise from the engine, providing a smoother ride. Typically made from a combination of metal and rubber, engine mounts help keep the engine aligned and prevent it from shifting during operation.

Functions of Engine Mounts

How common is it for engine mounts to break? Engine mounts serve several important functions:

- Vibration Absorption: They absorb and dampen engine vibrations, making the ride more comfortable.

- Engine Alignment: They keep the engine properly aligned with the transmission and other components.

- Noise Reduction: By minimizing engine movement, they help reduce engine noise within the cabin.

Frequency of Engine Mount Failure

How Common Is Engine Mount Failure?

Engine mount failure is not an everyday occurrence but is more common than many might think. How common is it for engine mounts to break? Several factors can contribute to the likelihood of engine mount issues:

- Age of the Vehicle: Older vehicles are more prone to engine mount wear and tear due to the natural degradation of materials over time.

- Driving Conditions: Vehicles that endure rough driving conditions, such as off-roading or heavy towing, are at a higher risk of engine mount failure.

- Engine Type and Mount Design: The type of engine and the design of the engine mounts can affect their durability and susceptibility to failure.

Typical Lifespan of Engine Mounts

Engine mounts generally last between 60,000 to 100,000 miles, but this can vary based on driving habits and vehicle maintenance. Regular inspections and maintenance can help extend their lifespan.

Causes of Engine Mount Failure

Common Reasons for Engine Mount Breakage

How common is it for engine mounts to break? Engine mounts can fail for various reasons, including:

- Wear and Tear: Over time, the rubber in engine mounts can deteriorate, leading to cracking or splitting.

- Excessive Vibration: Engine imbalance or misalignment can cause excessive vibration, putting extra stress on the mounts.

- Fluid Leaks: Engine oil or coolant leaks can weaken the rubber in engine mounts, leading to failure.

- Impact Damage: Accidents or hitting road debris can cause physical damage to engine mounts.

Signs of Engine Mount Problems

Recognizing the signs of engine mount failure early can prevent further damage to your vehicle:

- Excessive Vibration: If you notice increased vibrations or a rough ride, it could be a sign that your engine mounts are worn out.

- Engine Movement: Unusual engine movement, such as tilting or shifting, may indicate a problem with the mounts.

- Noise: Clunking or banging noises from the engine compartment when accelerating or braking can be a symptom of faulty engine mounts.

- Warning Lights: Some vehicles may trigger warning lights or error messages related to engine or transmission issues if the mounts are failing.

Diagnosing Engine Mount Issues

How to Inspect Engine Mounts

How common is it for engine mounts to break? To diagnose potential engine mount issues:

- Visual Inspection: Check for visible signs of wear, such as cracks or leaks in the rubber.

- Check for Movement: With the engine off, have someone start the vehicle while you observe the engine for excessive movement.

- Listen for Noises: Pay attention to any unusual noises that occur when accelerating or decelerating.

Professional Diagnosis

If you suspect engine mount issues but are unsure, it’s best to consult a professional mechanic. They can perform a more thorough inspection and provide a definitive diagnosis.

Preventing Engine Mount Failure

Regular Maintenance Tips

Preventing engine mount failure involves routine maintenance and care:

- Regular Inspections: Have your engine mounts inspected during routine maintenance checks.

- Address Leaks Promptly: Repair any engine oil or coolant leaks to prevent damage to the mounts.

- Avoid Rough Driving: Minimize rough driving conditions that can stress the engine mounts.

Upgrading Engine Mounts

In some cases, upgrading to higher-quality engine mounts can enhance durability:

- Performance Mounts: Consider performance or heavy-duty mounts if you frequently drive under strenuous conditions.

- OEM vs. Aftermarket: Decide between original equipment manufacturer (OEM) mounts and aftermarket options based on your vehicle’s needs and driving habits.

What to Do If Engine Mounts Break

Immediate Steps

If you experience engine mount failure:

- Stop Driving: Pull over safely to prevent further damage to your vehicle.

- Inspect for Damage: Check for visible damage or unusual engine movement.

- Contact a Mechanic: Arrange for a professional inspection and repair as soon as possible.

Repair and Replacement

Engine mount replacement is usually straightforward for a qualified mechanic. The process typically involves:

- Removing the Old Mounts: The mechanic will carefully remove the old engine mounts.

- Installing New Mounts: New mounts are installed, ensuring proper alignment and fit.

- Testing: The mechanic will test the vehicle to ensure that the new mounts are functioning correctly.

Engine Mount Replacement Cost

Understanding the Costs

Replacing engine mounts can vary in cost depending on several factors:

- Type of Vehicle: Luxury or high-performance vehicles may have more expensive mounts and labor costs.

- Location and Labor Rates: Costs can differ based on geographic location and the shop’s labor rates.

- Parts Quality: OEM parts are generally more expensive than aftermarket options but may offer better reliability.

Average Costs

On average, engine mount replacement costs range between $200 to $600 per mount, including parts and labor. It’s important to get a detailed estimate from your mechanic before proceeding with repairs.

Enhancing Vehicle Longevity

How Proper Maintenance Helps

Regular maintenance not only extends the lifespan of your engine mounts but also contributes to overall vehicle health:

- Routine Inspections: Regularly check your engine mounts and other critical components.

- Timely Repairs: Address any issues promptly to prevent further damage.

- Preventive Measures: Follow recommended maintenance schedules and avoid stressing the vehicle with rough driving or heavy loads.

Investing in Quality Parts

Investing in high-quality engine mounts can pay off in the long run:

- Durability: Quality parts often last longer and provide better performance.

- Reduced Repairs: Fewer replacements and repairs mean less hassle and cost over time.

- Enhanced Performance: Better mounts contribute to a smoother and quieter ride.

Choosing the Right Engine Mounts

OEM vs. Aftermarket Engine Mounts

When it comes to replacing engine mounts, you have two main options: OEM (Original Equipment Manufacturer) and aftermarket. Each has its benefits:

- OEM Engine Mounts: These are manufactured by the vehicle’s original maker and are designed to match the exact specifications of your vehicle. They offer superior fit and reliability but can be more expensive.

- Aftermarket Engine Mounts: These are produced by third-party manufacturers. While often more affordable, their quality can vary. Choosing high-quality aftermarket options can provide good performance and durability.

How to Choose Quality Engine Mounts

When selecting engine mounts, consider the following factors:

- Material: Ensure the mounts are made from high-quality materials such as durable rubber or metal composites that can withstand engine vibrations and heat.

- Fitment: Verify that the mounts are specifically designed for your vehicle’s make and model to ensure proper alignment and performance.

- Reviews and Ratings: Check customer reviews and ratings to gauge the reliability and performance of the engine mounts you’re considering.

DIY Engine Mount Replacement

When to Consider DIY

If you have mechanical experience and the necessary tools, replacing engine mounts yourself can save money. However, it requires careful attention to detail and safety. Here’s a basic overview of the process:

- Preparation: Ensure the vehicle is securely lifted and supported. Disconnect the battery and any components obstructing access to the engine mounts.

- Removal: Carefully remove the old engine mounts. This often involves unbolting the mounts and lifting the engine slightly to remove them.

- Installation: Position the new mounts and secure them with bolts. Ensure they are properly aligned and tightened to manufacturer specifications.

- Testing: Reconnect any components you disconnected and test drive the vehicle to ensure the mounts are functioning correctly and there are no unusual noises or vibrations.

When to Seek Professional Help

If you’re not confident in your mechanical skills or lack the required tools, it’s best to have a professional handle the replacement. A qualified mechanic can ensure the job is done correctly and safely.

Conclusion

Engine mount failure, while not extremely common, is a critical issue that can affect your vehicle’s performance and safety. By understanding the causes, symptoms, and preventive measures, you can ensure that your engine mounts remain in good condition and address any problems promptly. Regular maintenance and attention to your vehicle’s needs will help you avoid unexpected issues and enjoy a smoother, safer ride.