Engine braking, a term often synonymous with “Jake brake,” is a technique that leverages the engine’s power to slow down a vehicle. Unlike traditional brakes that rely on friction, engine braking harnesses the engine’s internal components to create a braking force. This method offers several advantages, including improved vehicle control, enhanced fuel efficiency, and reduced wear on traditional brakes. In this comprehensive guide, we will delve into the intricacies of engine brakes, exploring how they work, their benefits, and considerations for optimal use.

How Do Engine Brakes Work?

Engine brakes primarily operate by converting the engine into a temporary air compressor. This process involves:

- Closing the throttle: When the driver releases the accelerator, the airflow into the engine is significantly reduced.

- Creating a vacuum: This reduction in airflow generates a vacuum within the engine’s intake manifold.

- Compressing air: The engine’s pistons, instead of drawing in fuel and air for combustion, now compress the remaining air in the cylinders.

- Generating braking force: This compression process creates resistance, slowing down the engine. The engine’s connected drivetrain then transfers this braking force to the wheels.

Types of Engine Brakes

While the fundamental principle remains the same, there are two primary types of engine:

1. Compression Release Engine Brakes (Jake Brakes)

- Mechanism: These brakes involve a mechanical system that releases compression in the cylinders at a specific point in the engine cycle. This abrupt release of pressure creates a powerful braking effect.

- Common in: Heavy-duty trucks and buses.

2. Exhaust Brake

- Mechanism: This type of engine brake redirects exhaust gases back into the engine, increasing backpressure and creating a braking effect.

- Common in: Many modern vehicles, including passenger cars and SUVs.

Benefits of Engine Braking

Engine brakes offer several advantages:

- Improved Vehicle Control: Especially on downhill grades, engine braking helps maintain vehicle speed, reducing reliance on traditional brakes and preventing overheating.

- Enhanced Fuel Efficiency: By reducing the need for constant braking, engine braking can contribute to better fuel economy.

- Reduced Brake Wear: Less reliance on traditional brakes extends their lifespan and reduces maintenance costs.

- Increased Driver Confidence: The ability to control vehicle speed effectively enhances driver safety and confidence.

How to Use Engine Brakes Effectively

To maximize the benefits of engine braking, follow these guidelines:

- Plan Ahead: Anticipate downhill slopes and adjust your speed accordingly.

- Downshift Gradually: Shift gears progressively to match the vehicle’s speed and load.

- Use in Combination with Service Brakes: Engines are a valuable tool but should not replace traditional brakes entirely.

- Consider Driving Conditions: The effectiveness of engine braking can vary based on factors like road conditions, vehicle load, and engine type.

Engine Braking and Driver Comfort

While engine braking offers numerous advantages, it’s essential to consider driver comfort. Some engine brake systems can produce a distinctive noise, often referred to as “Jake brake noise.” This noise can be perceived as intrusive, especially in urban areas.

To mitigate this issue, many engine brake systems incorporate features like noise reduction technology or adjustable braking levels. Additionally, drivers can become accustomed to the sound over time.

Engine Braking and Environmental Impact

Engine braking can indirectly contribute to reduced environmental impact by improving fuel efficiency and reducing brake wear, which generates less brake dust. However, it’s essential to note that the overall environmental impact depends on various factors, including the vehicle’s overall efficiency and the specific engine brake technology employed.

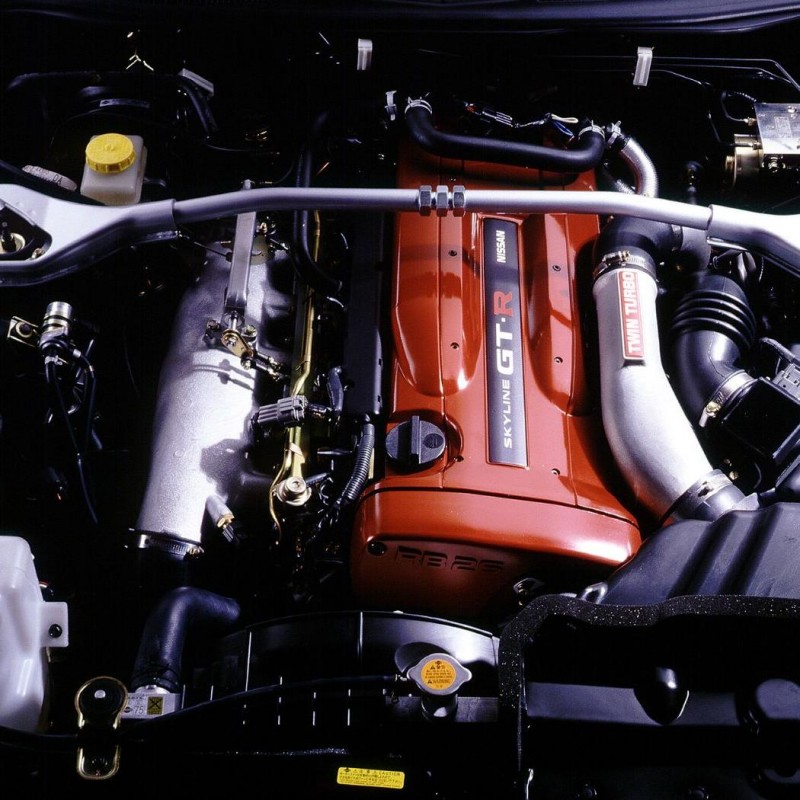

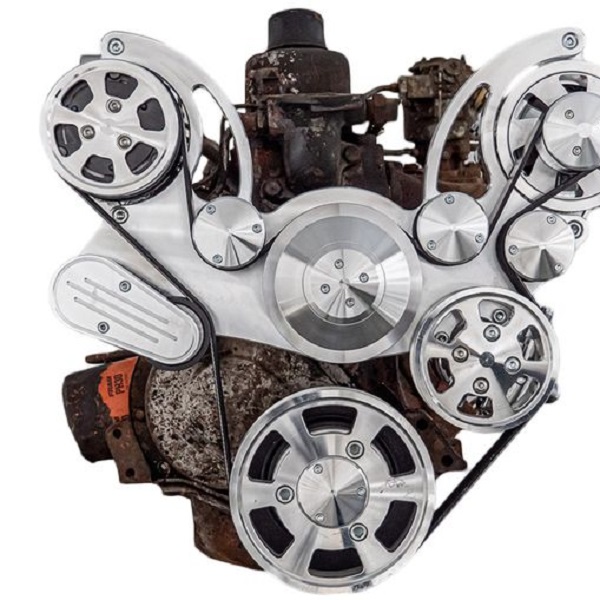

Understanding Engine Brake Components

While we’ve established the fundamental concept of engine braking, let’s explore the specific components involved in this process. A clear understanding of these elements will enhance your appreciation for the technology behind engine brakes.

Compression Release Mechanism

For compression release engine , the heart of the system lies in the compression release mechanism. This intricate component controls the timing of valve operation to release compressed air from the cylinders, generating the braking force. Advanced systems often incorporate electronic controls for precise operation and optimal performance.

Exhaust Brake Valves

Exhaust brakes utilize a series of valves to redirect exhaust gases back into the engine. These valves are strategically placed to create backpressure, which increases the engine’s workload and generates braking force. Modern exhaust brake systems may incorporate variable valve timing for adjustable braking intensity.

Electronic Control Units (ECUs)

Many contemporary engine brake systems rely on sophisticated electronic control units (ECUs). These computer brains monitor various engine parameters, such as speed, load, and throttle position, to optimize engine brake performance. ECUs also play a crucial role in coordinating the interaction between the engine brake and other vehicle systems.

Engine Braking and Different Vehicle Types

Engine braking is not a one-size-fits-all technology. The implementation and effectiveness of engine brakes vary across different vehicle types.

Heavy-Duty Trucks

Heavy-duty trucks, such as semi-trailers and construction vehicles, often employ powerful compression release engine brakes (Jake brakes) to manage steep grades and heavy loads. These vehicles require substantial braking force to maintain control, and engine excel in this demanding environment.

Passenger Cars and SUVs

While less common in passenger cars and SUVs, exhaust brakes are becoming increasingly prevalent. These vehicles benefit from the improved fuel economy and enhanced vehicle control offered by engine braking. Additionally, many modern cars incorporate regenerative braking systems, which capture energy during deceleration and store it in the vehicle’s battery for later use.

Hybrid and Electric Vehicles

Hybrid and electric vehicles utilize regenerative braking as their primary form of energy recovery. By converting kinetic energy into electrical energy, these vehicles can extend their driving range and reduce reliance on traditional friction brakes.

Myths and Misconceptions About Engine Brakes

There are several misconceptions surrounding engine brakes. Let’s dispel some common myths:

- Myth 1: Engine damage the engine: Properly designed and maintained engine do not harm the engine. In fact, they can help prolong engine life by reducing the strain on traditional brakes.

- Myth 2: Engine brakes are only for heavy-duty trucks: While compression release engine brakes are more common in heavy-duty trucks, exhaust brakes are increasingly found in passenger cars and SUVs.

- Myth 3: Engine brakes are inefficient in wet conditions: Engine can be effective in wet conditions, but the overall braking performance may be influenced by tire traction.

Maintaining Your Engine Brake System

While engine brakes are designed for durability, proper maintenance is essential to optimize their performance and longevity. Here are some key maintenance tips:

Regular Vehicle Maintenance

- Adhere to recommended service intervals: Regular oil changes, filter replacements, and tune-ups contribute to overall engine health, indirectly benefiting the engine brake system.

- Inspect brake components: Ensure that traditional brake components, such as pads and rotors, are in good condition. Overreliance on engine can accelerate wear on these components.

Specific Engine Brake Maintenance

- Compression Release Engine Brakes:

- Regular inspection of the compression release mechanism for wear and tear.

- Proper adjustment of compression release timing is crucial for optimal performance and noise reduction.

- Exhaust Brakes:

- Check for leaks in the exhaust system, as these can affect engine brake efficiency.

- Inspect exhaust brake valves for proper operation and wear.

Driver Practices for Engine Brake Longevity

- Avoid excessive engine braking: While engine brakes are beneficial, overuse can lead to premature wear.

- Smooth gear shifts: Harsh downshifts can put additional stress on engine components.

- Listen for unusual noises: Any unusual sounds from the engine or exhaust system should be investigated promptly.

Engine brakes are a valuable asset for drivers seeking improved vehicle control, enhanced fuel efficiency, and reduced brake wear. By understanding how they work and utilizing them effectively, drivers can experience the benefits firsthand. While the noise associated with some engine brake systems may be a consideration, technological advancements and driver adaptation can help mitigate this issue.

Ultimately, engine braking is a tool that, when used appropriately, can contribute to a safer, more efficient, and environmentally friendly driving experience.